Capabilities

Integrity, Life Extension & Monitoring

Advanced engineering services and tools to simplify asset operations and maintenance, minimise risk of failure, and prolong asset life. These services are provided in collaboration with Clarus Subsea Integrity, a division of 2H.

Discuss a project with us

Get in touchContact us

If you have a project we can help with or need some technical advice, please get in touch! One of our engineers will be happy to have a chat. Please provide some details below and and we will respond as soon as we can.

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Dharmik Vadel

Vice President, Clarus Subsea Integrity, USA

About

Dharmik is Vice President of Clarus Subsea Integrity and has led the company since it's inception in January 2015, responsible for business management and global growth of the organization.

Dharmik has over 18 years of experience in the development, implementation and management of integrity programs. He has led the development of digitalisation services with products such as iCUE - Clarus’ cloud-based IM software, Inspection APP - for digitalising inspection workflows,and Anomaly APP – image recognition AI for visual anomaly detection. His areas of expertise include digital solutions for asset lifecycle, corrosion management programs (RBI), delivering risk mitigation solutions, and life extension studies. Dharmik holds an M.S. in Environmental Engineering from Oklahoma State University and a bachelor’s in Civil Engineering from REC Calicut India.

Energy production is a costly business.

We help keep assets producing to maximise the ROI.

Preventing asset failure and extending asset life is essential to maximise operations, minimise costs and ensure profitability. Whether it’s for a single component or an entire system, we have the tools and know how to help clients understand asset condition, prove fitness for service and extend the life of their assets.

Predict and prevent failure before it happens

We believe the key to getting the most out of your asset is being proactive. To do that, we develop easy-to-follow roadmaps to simplify the integrity management process. We start by establishing the baseline condition and then prepare a structured, risk-based plan of action. This approach helps prevent failure before it happens and avoid the need for expensive remedial action.

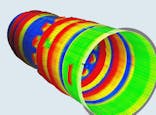

Digital tools to manage integrity more efficiently

We have developed a range of digital tools to streamline the integrity process. From data management systems to machine learning algorithms within digital twin that help predict fatigue and assess equipment condition. With better data at their fingertips and increased visibility of system health, our clients can focus on critical equipment, preventative maintenance and developing pragmatic engineering solutions.

Rapid response engineering when things don’t go to plan

Sometimes things out of our control can occur, no matter how well we prepare. When that happens, we have a team of integrity engineering specialists ready to mobilise. We provide rapid response assessments to identify and mitigate operational failures. We do what it takes to help clients minimize downtime and maintain operational safety, fast. Even if that means sending a team of engineers offshore to investigate.

Key Personnel

Ricky Thethi

Global Director, UK

About

Ricky is a Global Director based in 2H's London office having relocated from Houston in 2019 after spending almost 20 years in 2H’s Houston office as part of the management team.

Ricky is responsible for globalising the company’s integrity engineering capability and business across all of its offices in both the oil and gas and offshore wind sectors. One of his current focuses is digital transformation, including the use of machine learning and automation technology to improve the speed and accuracy of structural analysis, integrity monitoring and life extension.

Ricky obtained his degree in civil engineering with first-class honours from the University of Surrey in the UK, and is a fellow and Chartered Marine Engineer of the Institute of Marine Engineering, Science and Technology.

Insights

Dharmik Vadel

Vice President, Clarus Subsea Integrity, USA

About

Dharmik is Vice President of Clarus Subsea Integrity and has led the company since it's inception in January 2015, responsible for business management and global growth of the organization.

Dharmik has over 18 years of experience in the development, implementation and management of integrity programs. He has led the development of digitalisation services with products such as iCUE - Clarus’ cloud-based IM software, Inspection APP - for digitalising inspection workflows,and Anomaly APP – image recognition AI for visual anomaly detection. His areas of expertise include digital solutions for asset lifecycle, corrosion management programs (RBI), delivering risk mitigation solutions, and life extension studies. Dharmik holds an M.S. in Environmental Engineering from Oklahoma State University and a bachelor’s in Civil Engineering from REC Calicut India.